industrial gaskets

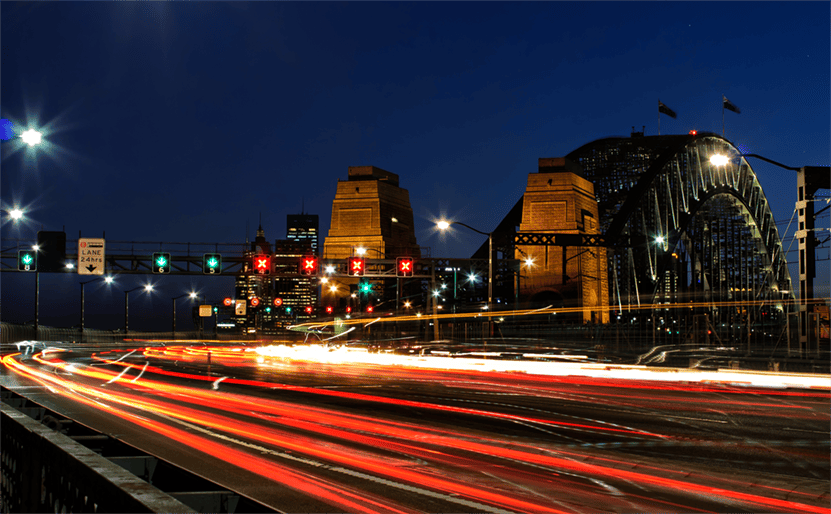

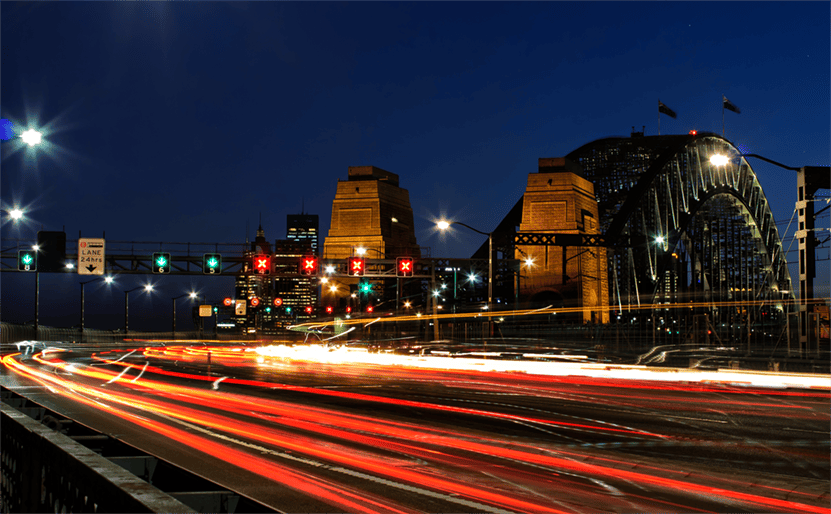

Australian Industrial Gasket Manufacturer

FAST EFFICIENT SERVICE & QUALITY PRODUCTS

Our experienced team have the knowledge required to provide trusted solutions for any project. We manufacture customized gaskets right here in Sydney. LELOX Gaskets and Seals, is a strategic partner for many of the leading names in gaskets, machinery materials and seals.

CUSTOM GASKETS

Our custom gaskets are manufactured to ensure quality, high-performance, by state-of-the-art technology and cutting-edge precision machinery at our local factory.

AUSTRALIAN MADE GASKETS

You can also be sure that no one offers better custom gaskets in Australia. We are known around Sydney for our competitive prices and our capability to deliver products that are technically correct. Call our proactive sales team for assistance.

HIGH QUALITY AFFORDABLE GASKETS

Over the years we developed the expert knowledge and experience in manufacturing custom items for a wide range of businesses. Offering our clients high quality die-cut gaskets, waterjet-cut and hand cut to suit multiple prerequisites at competitive prices.

MATERIALS TO SUIT YOUR NEEDS

Gaskets we manufacture can be made from a number of materials including, graphite, rubber, fibre, fiberglass, metallic, semi metallic and PTFE, just to name a few.

Leading Gasket Supplier and Manufacturer

At Lelox we are regarded as the top manufacturer and supplier for the following products:

- Gaskets in Sydney

- Custom gaskets

- PTFE gasket

- Die cut gaskets

- Topog-e boiler gaskets

- Custom rubber gaskets

- High temperature Gaskets

Rest assured that regardless of the size of your order, whether small or large, we will deliver it on time without compromising on quality.

FAQ

With our extensive industry experience, you can rely on us to offer the best service.

What are the different types of gaskets?

What is the best gasket material?

Why would you use a quality gasket?

The cost of a quality gasket is relatively low compared to the expense of downtime and corrective action experienced when a failure occurs. This can include danger to personnel, equipment and the environment. Not to mention labour costs associated with the repair and lost opportunity. Cheap imported products are not necessarily manufactured to the standards required in many industrial applications.

Never re-use gaskets as once they have been compressed a second time, they will not have the recovery properties required to seal in the majority of applications.

Should I use gasket sealant?

Why do gaskets fail?

If the correct gasket material has been selected, the failure is normally due to installation error. Other things that effect failure (loss of containment) are:

- The age of the gasket material

- How the gasket has been stored (flat, out of sunlight and ozone)

- Gaskets must be dry when installed

- Correct bolting must be used (grade, cleanliness, lubricated)

- Tightened up in sequence to the correct torque in at least three stages (30%, 60%, 100%)

- Flanges need to be parallel and not reliant on the bolts to pull flanges together

- Excursions from normal operating parameters. This means exceeding the capabilities of gasket material and joint design. Example: Thermal and pressure cycling